Current location: Home > Technology R & D > R & D advantages

The R&D team was established at the same time when the company was founded. Under the technical leadership composed of returned doctoral students and domestic outstanding postgraduate students, the core team has accumulated more than 20 years of experience in the industry.

The Company has established the

R&D cooperation platform with foreign experts from Japan, the United States

and South Korea, and the R&D personnel with doctorate, master degree or

above account for nearly 10%. Therefore, the Company can not only provide

customers with a complete set of processing processes and consumables involving

cutting, grinding, polishing and super mirror, but also develop special

products according to customers’ equipment environment on the site.

Zhongji Micro Material Co., Ltd.

attaches great importance to the quality of products, manages the production

process strictly in accordance with ISO9001 standards, controls the quality of

raw materials strictly and establishes a quality traceability system, and

control the whole process of production and establishes the quality inspection

system at all links, so as to guarantee the continuity and stability of

quality.

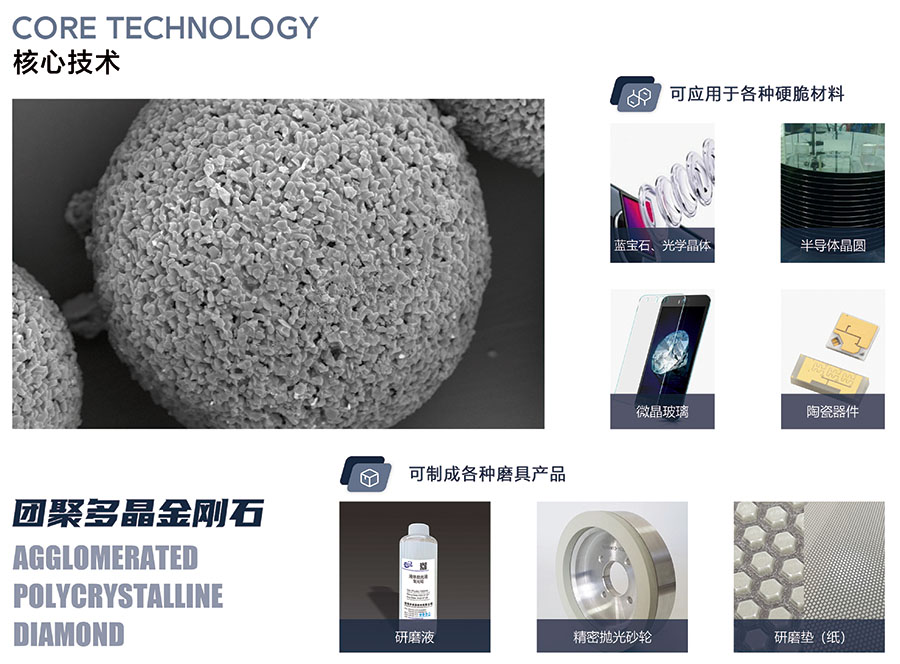

Suitable for all kinds of hard and brittle materials

Sapphire, Optical Crystal

Semiconductor Wafer

Microcrystalline Glass

Ceramic Device

Agglomerated Polycrystalline Diamond

Can be made into a variety of grinding tool products

Grinding fluid

Precision polishing wheel

Grinding pad (paper)

Agglomerated Polycrystalline Diamond

The agglomerated polycrystalline diamond has the advantages of multi-sharp blade, strong self-sharpening, and good surface effect after processing, so it is suitable for processing of hard and brittle materials.

History of Development

Agglomerated polycrystalline diamond is a concept created originally in 2018. After the research and development for two and a half years, the core technical team of Zhongji Micro Material Co., Ltd. initiated the first “agglomerated” diamond micro-powder in China, which is a new type of super-hard ultra-fine grinding material with the structure similar the stone concrete, in which the diamond particles + binding agent subject to precision processing are combined together and agglomerated into a number of spherical diamonds based on special processing, and finally applied to the precision grinding of hard and brittle materials such as ceramics, sapphire and silicon carbide.

Working Principle

The agglomerated polycrystalline diamond is formed by polymerization of tiny diamond powder, and there are a lot of edges on the surface, resulting in the high grinding rate;

Furthermore, during the process of grinding, the worn diamond will fall off, revealing the new diamond at the deeper layer, so as to realize self-sharpening and long effective grinding life;

Compared with mono-crystal and polycrystalline, the agglomerated diamond will not produce large diamond particles, so there will be no deep scratch during the process of the grinding, which is similar to polycrystalline.

Compared with polycrystalline, it is characterized by more environmental friendly forming process (No explosion, and no acid and alkali), lower cost, adequate production capacity, customized shape and size of agglomeration, and high adaptability.

Product Characteristics

It has excellent grinding performance, high removal rate and toughness, and self-sharpening;

Compared with mono-crystal diamond, it is less prone to surface scratch.

Compared with polycrystalline, it is more environmentally friendly, lower-cost, and highly adaptability;

It is more suitable for grinding of the workpiece whose surface is made of different hardness materials.

Application Fields

As a kind of precision grinding material, it is used for super-precision grinding and polishing of sapphire, SiC,magnetic head, hard disk, hard glass and crystal, ceramics and hard alloy, such as the thinning of LED sapphire and processing of silicon carbide substrate sheet.

It is also used to manufacture diamond thinning pad, polishing grinding wheel and so on.

Zhongji Micro Material Co., Ltd. attaches great importance to the quality of products, manages the production process strictly in accordance with ISO9001 standards, controls the quality of raw materials strictly and establishes a quality traceability system, and control the whole process of production and establishes the quality inspection system at all links, so as to guarantee the continuity and stability of quality.