Current location:Home > Application area >

Published on:2021-05-05 16:23:00Views:9270【Smallinlarge】

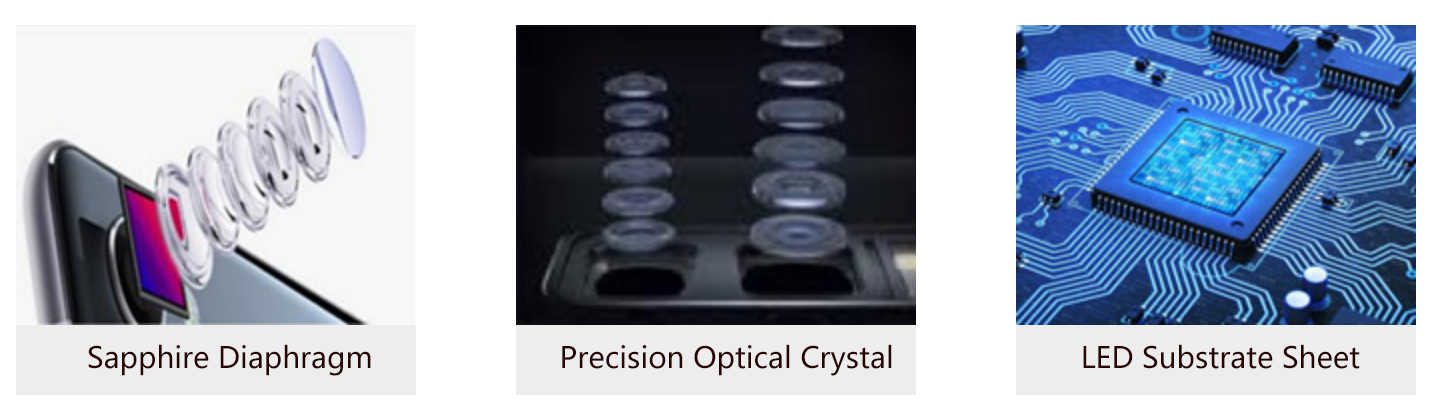

With the agglomerated polycrystalline diamond grinding fluid and the alumina polishing fluid developed by Zhongji Micro Material, it is possible to achieve the optimal polishing rate and the surface effect treatment for sapphire substrate sheet, sapphire diaphragm, sapphire optical chip, LED sapphire substrate, optical crystal, gem optical lens, optical glass, quartz, and other infrared crystal devices

|

Recommended Particle Size |

Diamond Agglomerated Powder |

Diamond Agglomerated Grinding Fluid |

Alumina Polishing Fluid |

Silicon Oxide Polishing Fluid |

|

15-40μm |

15-40μm |

1.0-1.5μm |

80-120nm |

|

|

15-40μm |

15-40μm |

|

|

Due to its characteristic of spherical multi-edge angle, the ball-like agglomerated polycrystalline diamond can maintain the high grinding force without scratch during the process of grinding and polishing. It is widely used for grinding of the hard and brittle materials such as sapphire, silicon carbide, and gallium nitride.

It has the ball-like shape feature, presenting multi-edge structure in microscope view, and showing slight luster of natural mineral;

It has higher cutting capability, and guarantees high precision polishing effect;

It has narrow distribution range of particle size, so as to achieve uniform surface roughness;

It has stable quality of products, and small difference between batches;

It can achieve ultra-high purity.

Suitable for processing of sapphire, such as grinding of LED chip, diaphragm, watch lens, mobile phone fingerprint identification sheet, and mobile phone camera lens, and other sapphire materials;

Processing of infrared crystal, such as the grinding of zinc selenide, germanium, silicon, zinc sulfide, calcium fluoride, magnesium fluoride, lithium niobate, lithium carbonate, and chalcogenide infrared material, and other infrared materials;

Processing of metal materials, such as stainless steel, die steel, titanium alloy, and other metal materials.

Polishing of sapphire optical chip, LED sapphire substrate, watch lens, crystal, gem optical lens, optical glass, quartz, and silicon wafer of optical fiber and of photovoltaic enterprise; polishing of germanium sheet, polishing of gallium arsenide; polishing of indium phosphide; polishing of zinc selenide; polishing of optical fiber connector; polishing of optical fiber patch cord; polishing of glass;

For recommended products or technical support, please contact our application engineers.