In the silicon carbide wafer manufacturing process, in order to ensure the smooth production of high-quality, high-performance products, every step of the operation needs to be very precise. Amo...

In the silicon carbide wafer manufacturing process, in order to ensure the smooth production of high-quality, high-performance products, every step of the operation needs to be very precise. Among them, the grinding and polishing of silicon carbide substrate is particularly important, because it directly affects the quality and performance of the chip. In order to achieve efficient and precise grinding and polishing, selecting the appropriate grinding material is the key. Today, we will discuss the important material of silicon carbide substrate polishing process - diamond grinding fluid.

1. Composition of diamond grinding fluid

Diamond, known for its excellent hardness and wear resistance, has an indispensable position in the field of grinding and polishing. Diamond grinding liquid is mainly composed of diamond powder, dispersant, suspension agent and lubricant. Among them, diamond powder is used as the main abrasive to physically grind the silicon carbide substrate. Dispersants and suspensions ensure that the diamond particles in the grinding fluid are evenly dispersed and prevent agglomeration. The lubricant reduces friction during grinding and ensures the smoothness and quality of the silicon carbide substrate surface.

2. Advantages of diamond grinding fluid

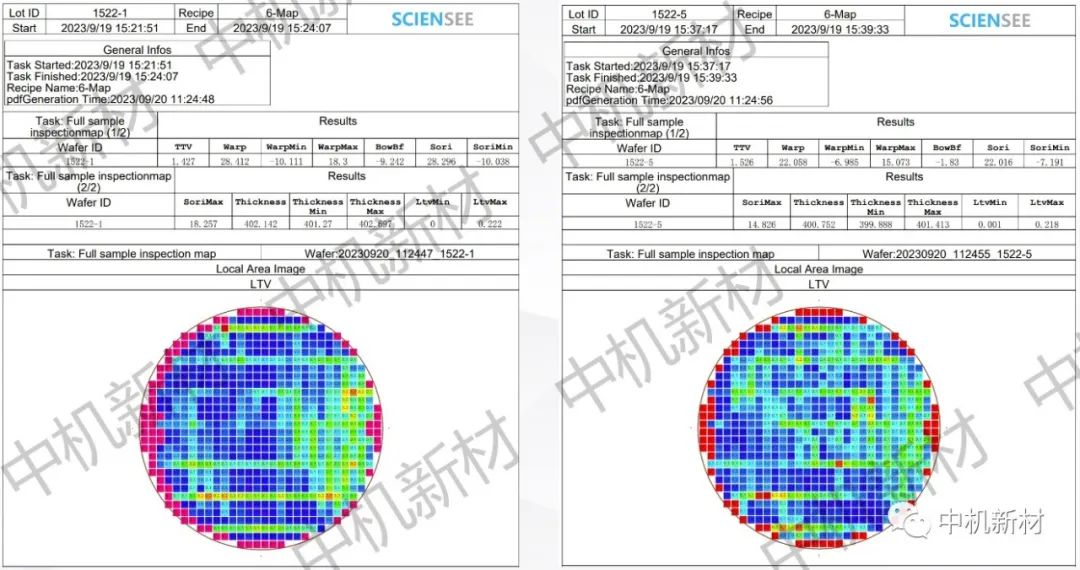

High efficiency: The high hardness and sharpness of the diamond powder make the grinding process more efficient, and the required flatness and finish can be obtained in a short time.

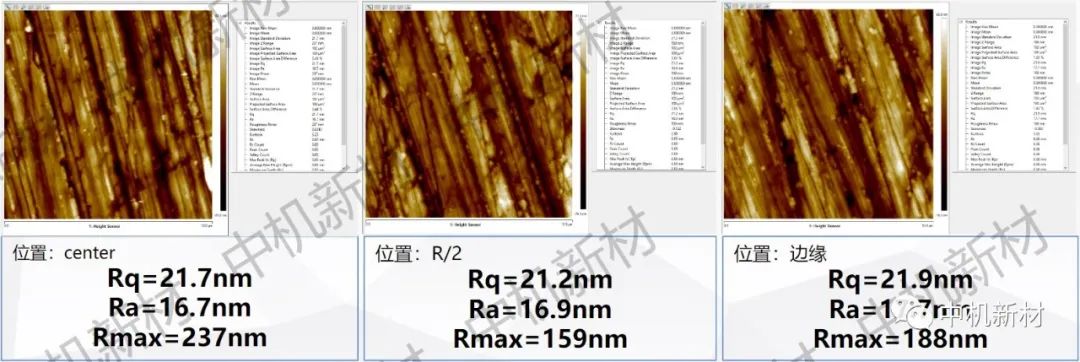

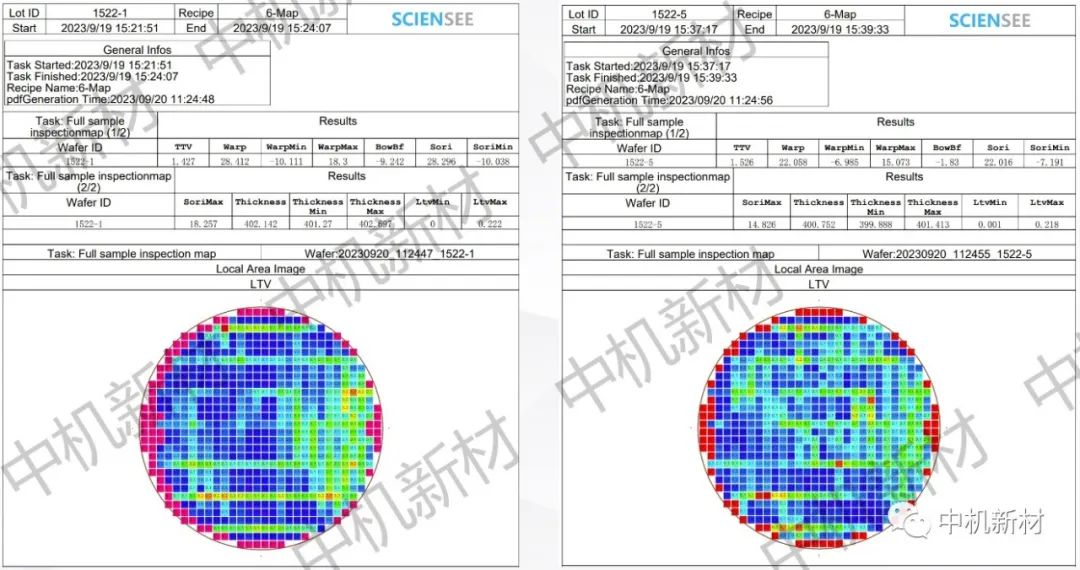

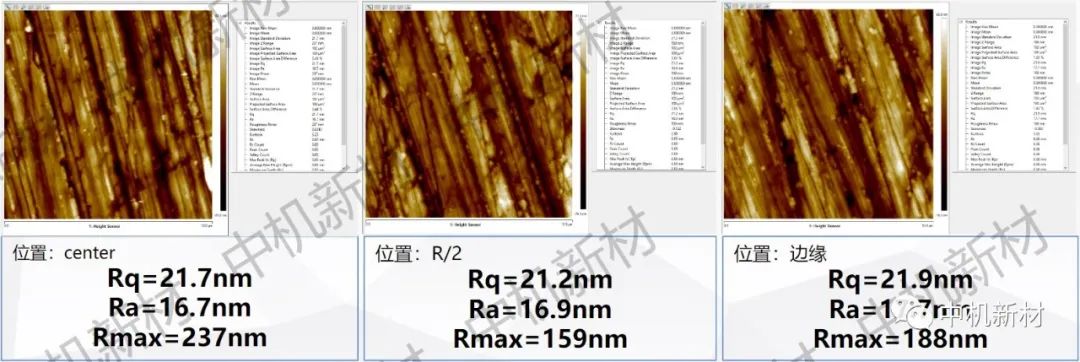

High precision: Due to the self-sharpness of the diamond and the uniform dispersion of the micro-powder, the wafer can maintain high precision and consistency during the grinding process.

A wide range of adaptability: Different particle sizes of diamond grinding fluids can be applied to different stages of grinding, from coarse grinding to hyperfine grinding, you can find the right product. 3. Zhongji New Material's diamond grinding fluid products

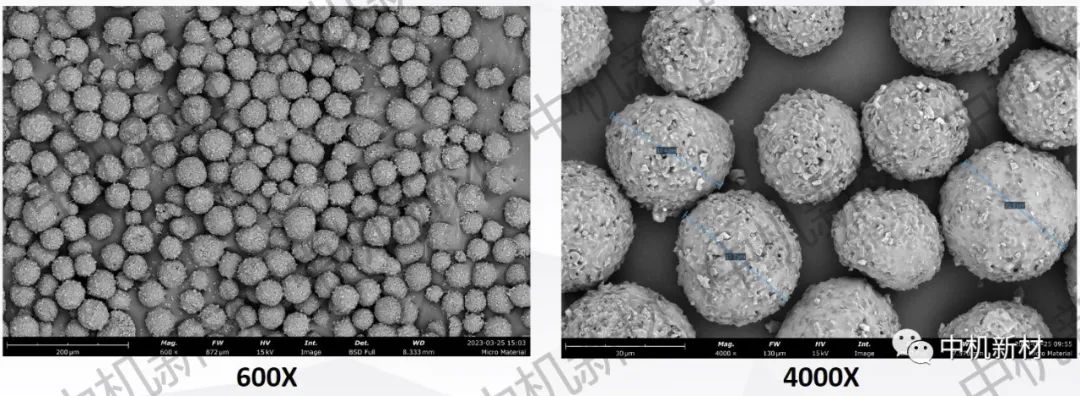

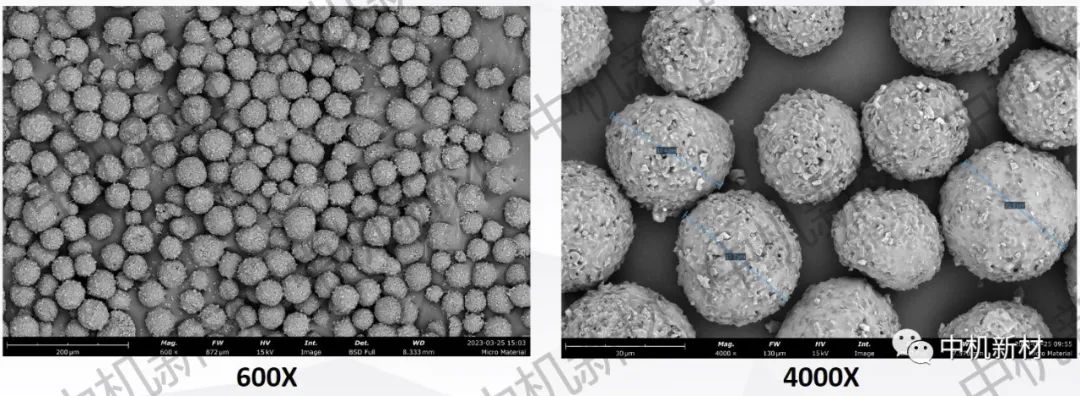

Agglomerated Diamond Grinding Liquid DLE1532

Among the many diamond grinding fluid suppliers, Shenzhen Zhongji New Materials Co., Ltd. stands out for customers by virtue of its high quality and high performance products. Zhongji New Material not only provides single crystal, polycrystalline, polycrystalline diamond grinding fluid, but also independently developed agglomerated diamond grinding fluid, which can meet the needs of different customers. The product has good dispersion and uniform particle size, which provides a solid guarantee for grinding and polishing of silicon carbide substrate.

With the continuous progress and development of the third generation semiconductor technology, the requirements for grinding and polishing silicon carbide substrates are becoming higher and higher. Diamond abrasive fluid, as a key material in this process, its importance is self-evident. With its high-quality products, Zhongji New Materials provides strong support for the semiconductor manufacturing industry, ensuring efficient and high-quality grinding and polishing effects.